EMAIL US

info@resonatetesting.comCALL US

+44 (0)28 90 736 390Resonate testing provides high quality fire, mechanical, and environmental test solutions and certification services across a wide range of industrial sectors. From Primes to SME’s, Resonate Testing provides a bespoke and tailored service to our customers.

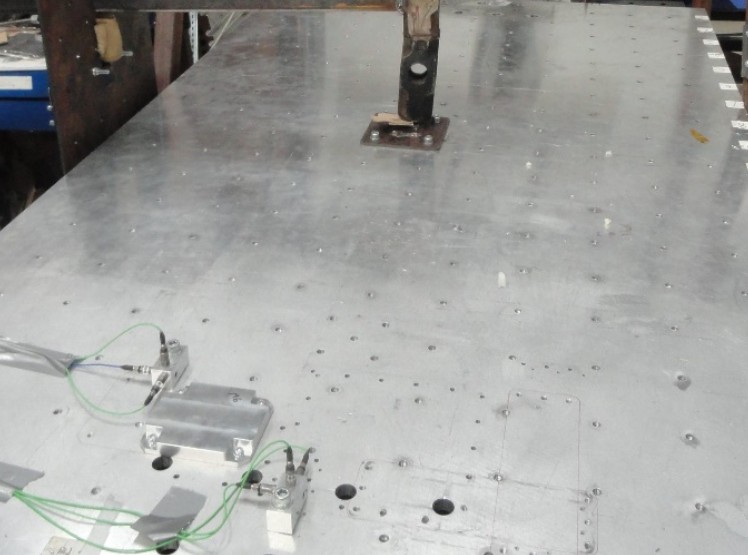

Our vibration test laboratory features several vibration tables capable of a wide range of frequencies, amplitudes, and spectrums. We are accredited to many of the common standards, including EN 60068, RTCA DO160, MIL-STD-810, for sinusoidal vibration including resonance tracking and dwell, random vibration classic shock, complex shock pulses, shock response spectrum (SRS) and combined shake and bake.

To assess their performance and safety, especially during transit, Resonate Testing offer a full range of battery tests (UN 38.3, SAE J2464, BS EN 62133-2, UN ECE R100) for verifying battery performance, durability, environmental, safety and lifecycle testing.

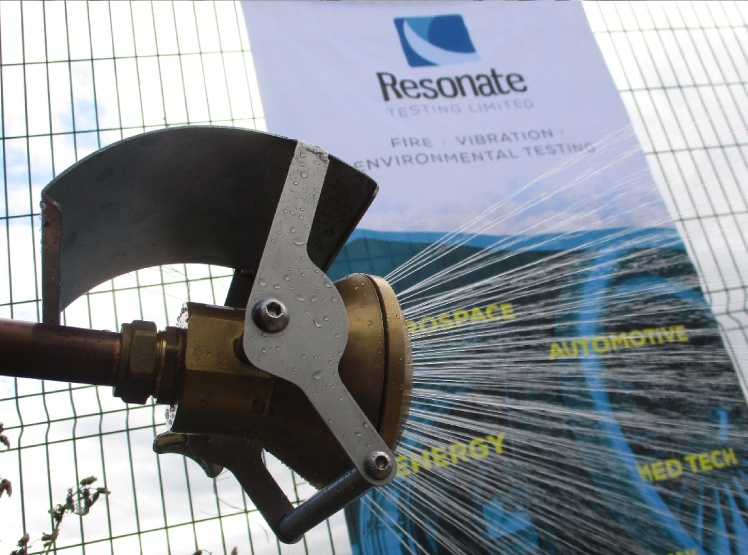

At Resonate Testing we have a dedicated and custom-built fire testing area and an in-depth knowledge capability to understand your specific fire or flammability test requirements. Our particular forte is fire penetration testing for aircraft powerplant certification (AC20-135, ISO 2865, AS1055), where a range of operational conditions can be included within the test. We can also carry out material fire testing for Seat Cushions, Cargo Liners and Insulation and Flammability testing (vertical, horizontal and 45 degrees) in accordance with FAA Fire Test Handbook.

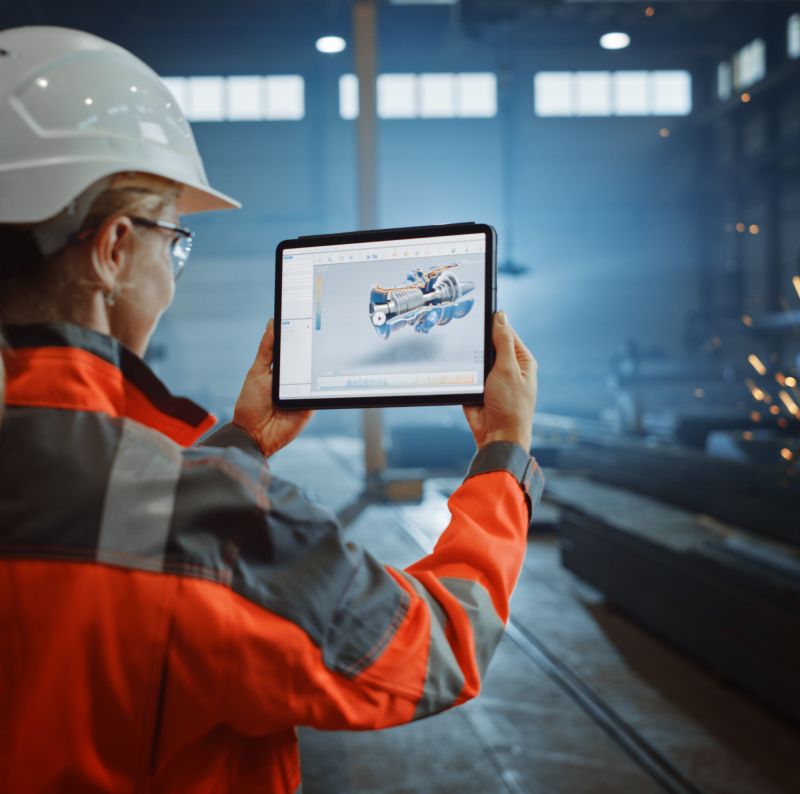

Clients increasingly avail of Resonate Testing's in-house capability to engineer, design, fabricate and instrument bespoke rigs and fixtures, capable of simulating operational conditions and to ensure the appropriate testing of components to the specifications required. Resonate testing keen focus on R&D supports our ability to assist a range of customers, across all industries. We can also support the full test process from the generation of test plans and procedures to test execution and results analysis.

A shock is a sharp transfer of energy into a mechanical system to test the system’s capability to survive a drop, hit, impact, fall, explosion or any other source of transient vibration. Resonate offer a ranging of tests including classic Shock, complex shock pulses, shock response spectrum (SRS) and Pyroshock. We cover IEC/EN 60068, RTCA DO160, MIL-STD-810, for example.

The packaging in which a product ships must withstand potential physical and environmental exposures from manual or automatic handling, storage and stacking, transport vibration from road, rail, sea or air transport, potential for fall/drop, as well as hot, cold or humid conditions. Our standard packaging tests are in accordance with International Safe Transit Association (ISTA) procedures and other international standards, such as MIL-STD-810, EN60068 and many of the ASTMs.

Testing can be carried out to determine resistance to ingress of sand, dust, water and other foreign objects in accordance with IEC 60529, MIL-STD-810, RTCA D0-160, DEF STAN 00-035 and ISO 20653.

We offer a wide range of environmental tests based on temperature, humidity and altitude. These include high and low temperatures, thermal cycling with rapid ramp rates (thermal shock) and combined testing over various ranges (IEC/EN 60068, RTCA DO160, MIL-STD-810, for example). We can also simulate exposure to salt fog/mist/spray, water ingress, dusty environments, fluids susceptibility, high and low pressures, while products undergo vibration or everyday operational requirements.

Resonate Testing is dedicated to supporting our customers in the transition to clean energy by offering comprehensive and reliable EV battery testing services. We understand that your needs and goals are paramount, and we are here to provide the expertise and support you require.

Resonate Testing is a family owned and operated ISO17025 accredited SME test facility located in Northern Ireland. Resonate Testing has the unique position of unfettered access to the EU, UK and global markets. We have a proven capability with propulsion system fire testing for large civil aircraft, and a range of environmental testing, complementing Vibration and SRS shock testing demonstrating full compliance for space launch vehicles, for example. This expertise and knowledge has been easily extended to various industries and other unique test applications.

Maintaining a strong engineering team, we differentiate ourselves by demonstrating our ability to support clients fully, as a complete Test Service Facilitator.

Our state-of-the-art Vibration & Fire Test house has the ability to test products from a number of industries including –